Many industrial buildings have less than ideal conditions for the machines they house. Roofing might be uninsulated, air becomes laden with moisture, lubricants and product. Machines that need compressed air may also receive doses of condensate.

Cooling systems draw this brew through filters and circulate it around sensitive places on each machine. Filters are not always maintained or appreciated for the protection they can provide.

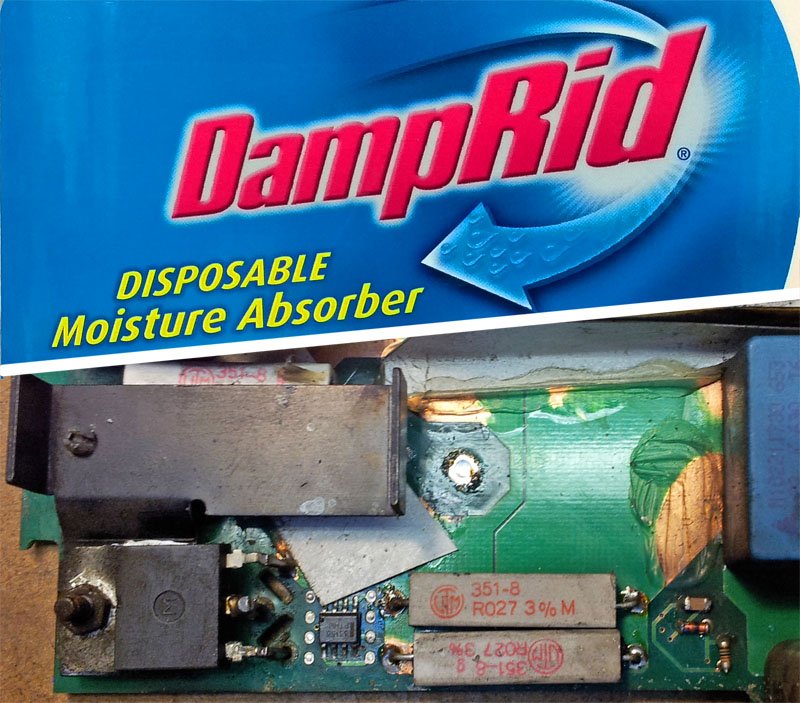

Over time we see debris built up on circuit boards, particularly on warm surfaces. It absorbs moisture and can lead to corrosion. Corroding copper tracks turn black underneath the protective solder-mask on circuit boards. In time we know these tracks will fail.

There are preventative measures that will help, but, even if it seems like a good idea, NEVER EVER PUT DAMPRID IN OR NEAR A MACHINE.

DampRid does a superb job at what it is designed to do. It absorbs lots of moisture. Unfortunately, it has a serious drawback that will kill your machine much faster than moisture will.

Why? DampRid’s active ingredient is Calcium Chloride (CaCl2) which reacts with two molecules of water (2H2O) and produces heat. The resultant ‘brine’ contains Ca(OH)2 + 2HCl, that is Calcium Hydroxide and Hydrochloric Acid.

The official DampRid Safety Data Sheet states “This material is classified as hazardous under OSHA regulations”. The really serious clue is actually in the Fire Fighting Measures section. “Do not pour water directly on the material. Avoid breathing corrosive vapors; keep upwind.” Guess what, those corrosive vapours come from hydrochloric acid.

So, if you’ve been using DampRid to keep your machinery dry it would be prudent to get it out quickly and dispose of it safely. Call in someone you trust to thoroughly check the machine and circuit boards for corrosion. In all but the most serious cases we are able to recover damaged boards and have them operational again.

Where moisture is likely to be an issue, we recommend placing fresh bags of silica gel in machines to keep it under control. Replace the gel bags and air filters before they become ineffective.

Photo above shows circuit board damaged by fumes from DampRid. Note the green protective solder-mask has flaked off the copper, and the corrosion on the transistor (left side).