SMARTsolver

- Home

- SMARTsolver

An Industrial Electronic Tester for testing.

- Resolvers

- EnDat Encoders

- Incremental Encoders

- Hiperface Encoders

With Special Features to allow:

- Easy Calibration Recording

- Guided Re-calibration of Servo Motors

This unit was designed to high standards by the same engineers who diagnose complex industrial machines. It had to be useful and practical, intuitive and easy to use. After all, they wanted it to be useful for themselves.

Generally, it will:

- Automatically identify signals from the encoder under test.

- Allow you to confirm specifications, output type, signal connections, zero position.

- Determine the electrical zero rotational position of the servo motor shaft.

- Apply a holding brake to the servo motor shaft at the zero rotational position to allow easy refitting of the encoder at the correct position.

Display modes:

- Live positional data (Pulses per revolution, encoder count, shaft angle).

- Speed and number of turns.

- Signal sources (Which wires are connected to identified signals).

- Jitter (quality of design and bearing wear).

- Motor rotational angle.

- Motor recalibration mode (with holding brake function).

Features

- Read motor / encoder calibration angle.

- Guide and assist with motor / encoder reattachment and recalibration.

- Ability to brake / stop the motor shaft at the correct calibration position.

Most rotational devices can be tested:

- Resolvers

- Incremental Encoders

- EnDat Bus Type Encoders

- Hiperface Bus Type Encoders (not DSL) (using different interface modules).

- Strobe output to signal Index position.

- Powered from internal AA batteries, or from USB-C charger / power bank.

- Optional Carry Case to keep the equipment together.

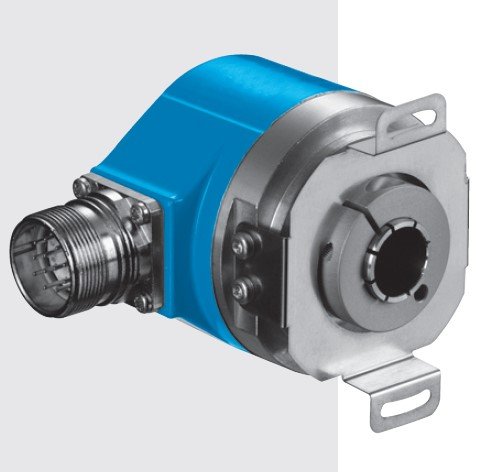

Rotary Encoders & Resolvers

Rotary encoders and resolvers are widely used in many industrial machines around the world. They are a critical sensor that provides feedback to computers and motor drives about physical positioning and moving shaft angles.

Traditional incremental encoders are still common, but now they compete with the likes of resolvers and digital encoders that work very differently. Examples of common digital encoders include EnDat & Hiperface amongst others (Hiperface DSL is not included – yet).

Encoders can be reliable while environmental conditions remain good. But they can cause issues when they start to become unstable due to wear and age.

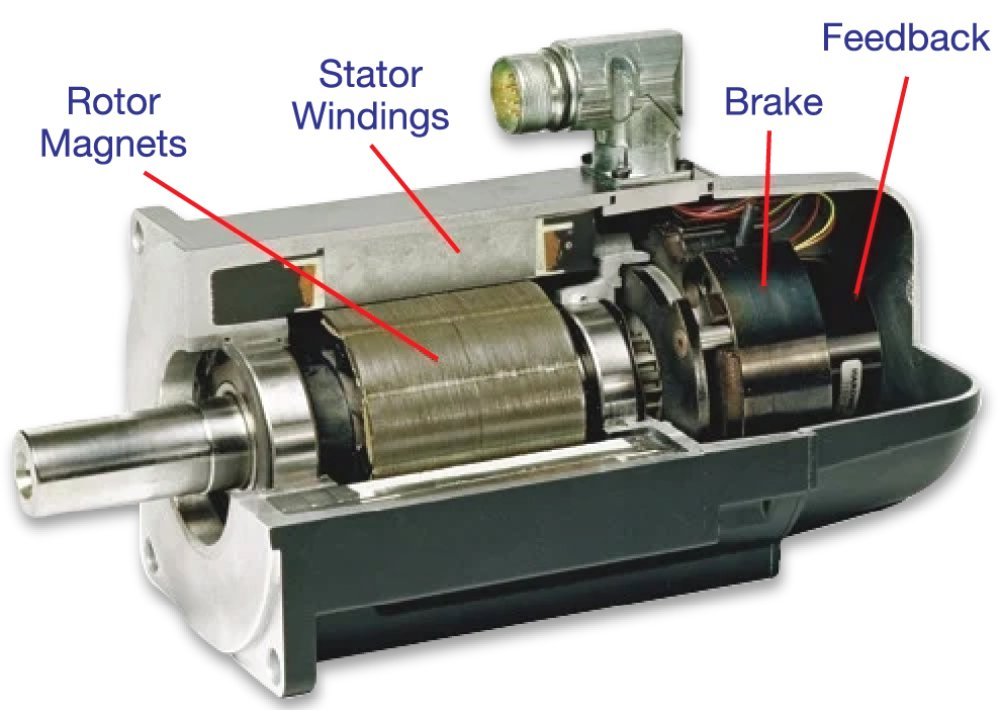

Typical industrial machines are packed with permanent magnet servo motors. Each one has an encoder buried inside.

The Problem with Servo motors

Servo motors use an internal encoder to provide angular feedback to the drive electronics. As a result the drive is able to create the best moving magnetic field for maximum torque and efficiency.

What is less well-known is that servo motors have a fixed rotational relationship between the motor shaft and the encoder shaft. If this angle is disturbed the motor will not perform well, if at all. The servo motor will draw high current when they’re out of alignment, even by just a few degrees.

Any motor servicing technician that is unaware of this relationship is in trouble from the moment they dismantle a permanent magnet servo motor. As soon as the relationship between motor and encoder is disturbed, the chances of the motor working again are very low.

To perform this task successfully special processes need to be utilised.

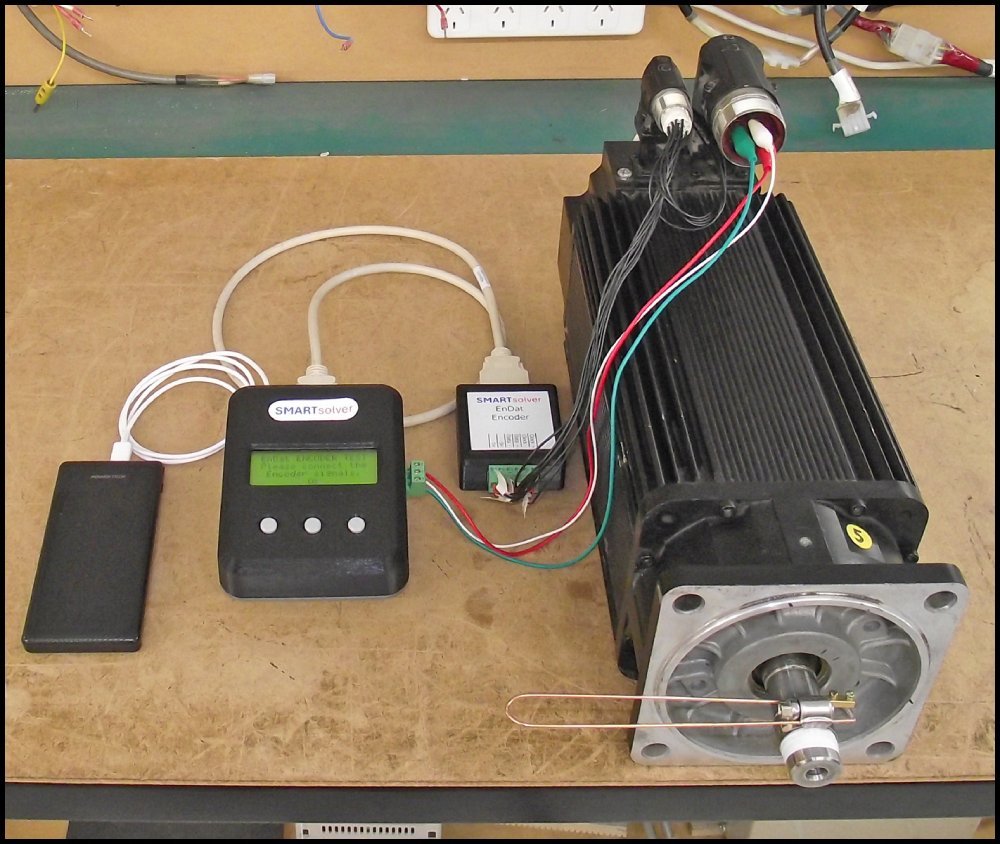

Our Solution

In the past, motors and encoders were physically measured and marked to record their static relationship. It worked, but it was not totally accurate and it was time consuming.

What if there were a way to electrically test a motor to determine the angle relationship to its encoder?

Furthermore. imagine a device that can prove the integrity of the encoder, establish the angular calibration, and guide someone through reassembly and recalibration once refurbishment is complete.

Enter the Attwood Electronics SMARTsolver. This industrial tester has been developed and proven by the company that made it their business to service drives and servo motors. The SMARTsolver does all of the above along with some unique extras that make the recalibration very straightforward.