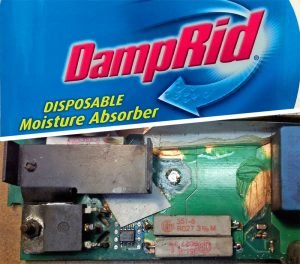

Industrial machines, even modern ones, have a vulnerability that is often overlooked. They contain hidden batteries that keep memory chips alive, protecting programs and settings from being lost or corrupted. At the end of their useful life, they will lose power. If not replaced they will eventually leak and corrode surrounding circuitry.

Some machines use PC hardware for high-level control. PCs usually have a Lithium Manganese battery, good for up to 10 years. A home or office PC would likely be discarded before then, but for an industrial machine the upgrade process is very much more complex.

Programmable Logic Controllers (PLCs) often have batteries to keep settings memory live and clock / calendar chips ticking over.

In less-common cases, machines rely on an Uninterruptible Power Supply (UPS) for power conditioning, or just to keep going long enough to shut down safely. UPS units have Sealed Lead Acid batteries inside and they degrade in as little as three years.

To avoid problems for our customers we’ve been going through our previous job records for useful information.

If we have replaced a battery, we’ll endeavour to contact the customer (or contractor) before the new battery is past its “best before” date. Depending on the battery chemistry it could be between three and ten years later.

Where we have worked on a unit that has an original battery, we’ll use the manufacture date to assume the battery age and extrapolate this to a replacement date.

For some machines, the battery replacement is straight-forward and often outlined in the machine manual. For others it requires a “hot-swap” operation where the memory is supported by external power while the battery is replaced.

Our advice:

- Do not allow Machine Operators to ignore a battery warning message.

- Get machines checked by someone you trust.